- Abelé 1757

- Agrapart

- Alfred Gratien

- Apollonis

- AR Lenoble

- Armand de Brignac

- Ayala

- Barons de Rothschild

- Beaumont des Crayères

- Benoît Lahaye

- Bergeronneau Marion

- Besserat De Bellefon

- Billecart - Salmon

- Blin

- Bollinger

- Bruno Paillard

- Canard Duchene

- Castelnau

- Cattier

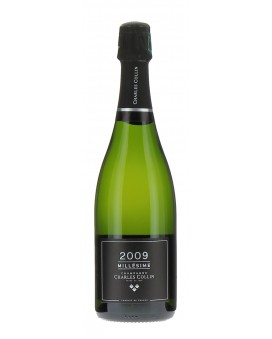

- Charles Collin

- Charles Heidsieck

- Chartogne-Taillet

- Chassenay d'Arce

- De Saint Gall

- De Sousa

- De Venoge

- Delamotte

- Demoiselle

- Deutz

- Devaux

- Diamant Vranken

- Dom Perignon

- Drappier

- Duval - Leroy

- Egly-Ouriet

- Epc

- Fleury

- Gosset

- Heidsieck & Co Monopole

- Henri Giraud

- Henriot

- Jacquart

- Jacquesson

- Jean-Noel Haton

- Joseph Perrier

- Konrat

- Krug

- Lafitte

- Laherte

- Lallier

- Lanson

- Larmandier-Bernier

- Laurent-Perrier

- Leclerc Briant

- Lombard

- Mailly Grand Cru

- Moet Et Chandon

- Montaudon

- Moussé Fils

- Mumm

- Napoleon

- Nicolas Feuillatte

- Pannier

- Paul Goerg

- Perrier Jouet

- Philipponnat

- Pierre Gimonnet

- Piper - Heidsieck

- Pol Roger

- Pommery

- Rare Champagne

- Louis Roederer

- Ruinart

- Salon

- Selosse

- Soutiran

- Taittinger

- Thienot

- Tsarine

- Veuve Clicquot

- Veuve Lanaud

Charles Collin Champagne

The Maison Charles Collin has been established on the Côte des Bars since 1952, and brings together more than 140 winegrowers. The vineyard covers nearly 330 hectares, 92% of which are Pinot Noirs and 8% Chardonnay.

In a constant concern of quality, this house ensures the totality of the elaboration of Champagne, from the hand harvest to the departure of the bottles. Discover champagnes with an excellent quality/price ratio!

CHARLES COLLIN Champagne

The traditional making process combined with a hi-tech production tool allow Cellar Masters to fully express their talent and thus, to ensure a top of the range quality.

Some figures about the House Charles COLLIN

-The house supplies the greatest champagne houses from their 140 hectares vineyard.

-850.000 bottles aimed to other champagne houses such as JACQUART.

-100.000 bottles for the brand Charles COLLIN.

-The house owns 2.5 million bottles which are left 3 years in the house’s cellars, and 5 years for cuvées Charles and Belle Gabrielle.

Champagne elaboration process

-Manual harvest: grape collecting and juice extraction using pneumatic presses.

-Vinification: transformation of must into clear wines, 1st “alcoholic” fermentation, then the wine is filtered and stays in tanks between 6 and 8 months. Tanks are made of stainless steel and are thermo-regulated.

-Blending: this is the cellar master work of art, to taste every clear wines in order to obtain a blend of the greatest cuvees.

-Tirage: when the blended wines are transferred inside bottles.

-Cellar aging (from 3 to 5 years in average), in order to begin the second fermentation stage called “prise de mousse” (foaming process).

-Riddling : using a gyropalette.

-Disgorgement: sediment’s extraction and addition of liquor dosage to determine Brut wines, Demi-Sec or Doux.

-Dressing: cork installation, label, back label and packing.

Trusted Reviews

97% of satisfied customers Shipping 24H

Order before 11AM Gift Message

free + 1200 références

in stock Storage

Hydro-regulated Secure Payment

Credit Card, Amex, Paypal, Bank transfer